3 Ways How To Use Laser Marking Services For Precision And Efficiency

In today’s fast-paced world, product identification, branding, and traceability have become crucial aspects for businesses across various industries. The ability to mark and engrave materials with precision and permanence has significantly evolved with the advent of laser marking technology.

Laser marking services have revolutionized the way companies approach product marking, offering numerous advantages over traditional methods. This article explores the ins and outs of laser marking services, their applications, benefits, and the industries that benefit from this cutting-edge technology.

3 Ways How To Use Laser Marking Services For Precision And Efficiency

Understanding Laser Marking

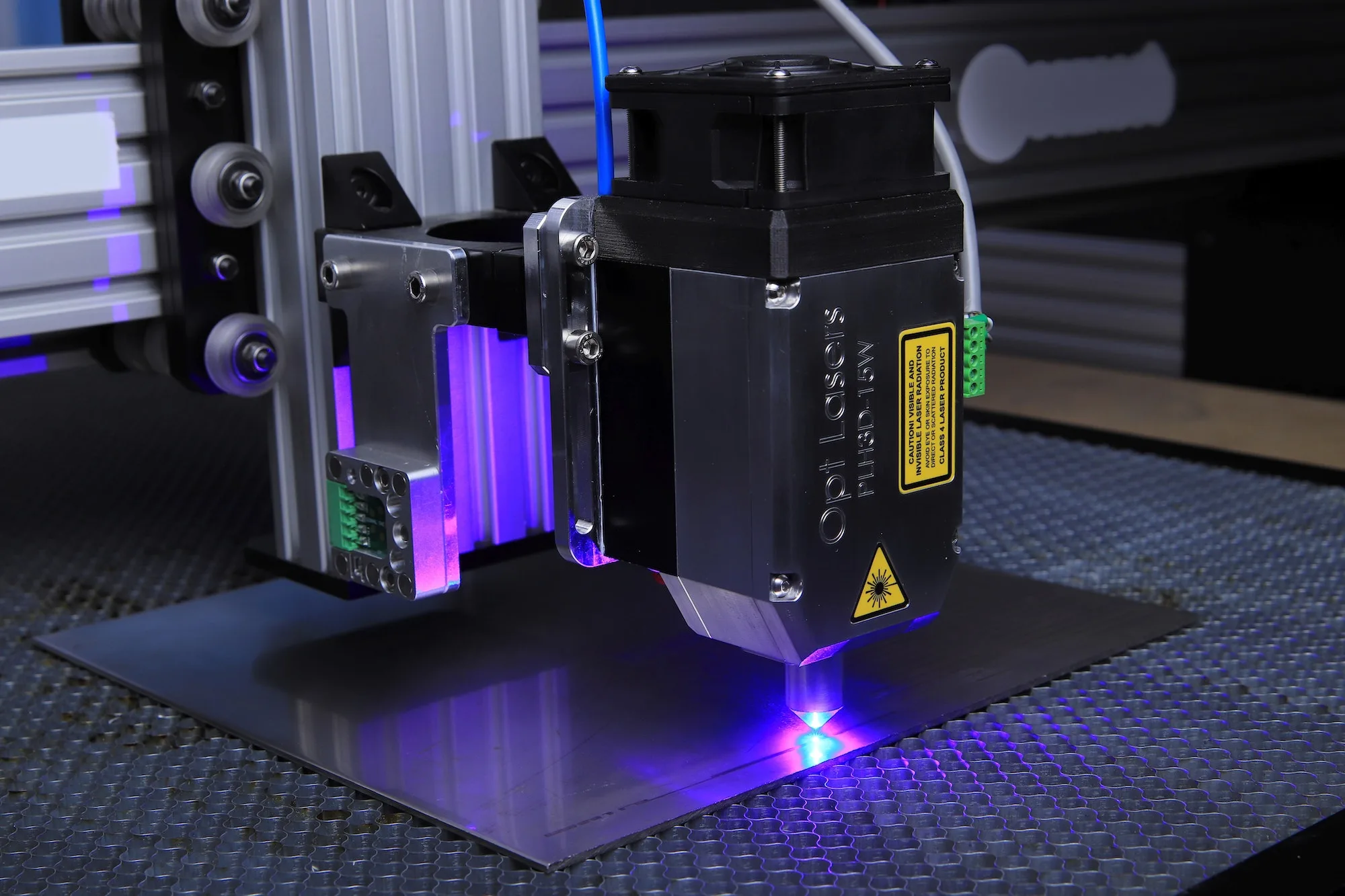

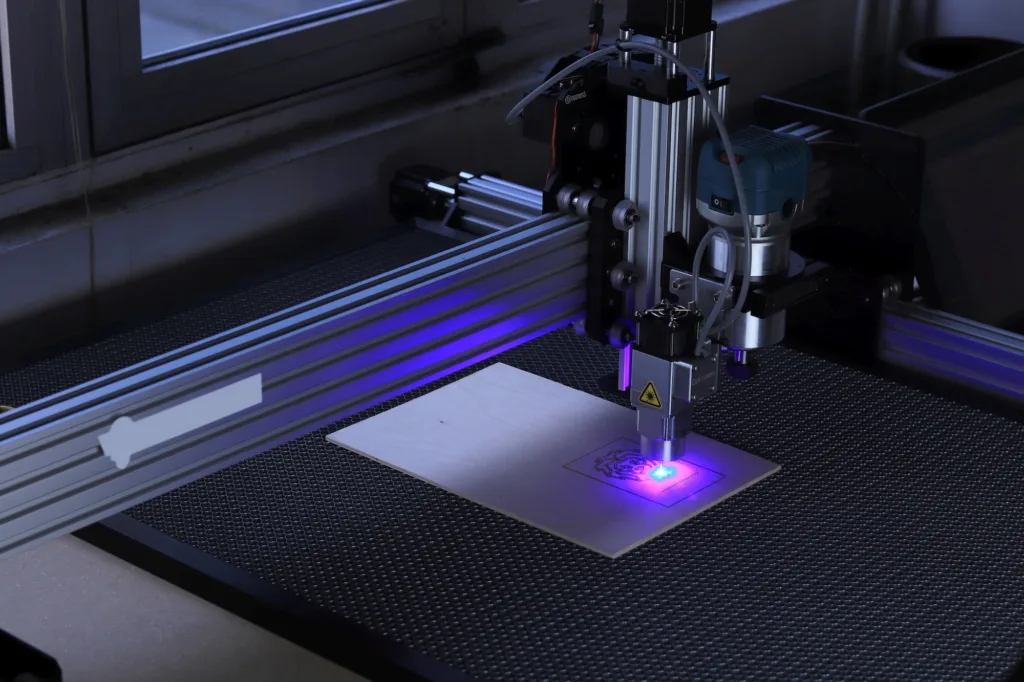

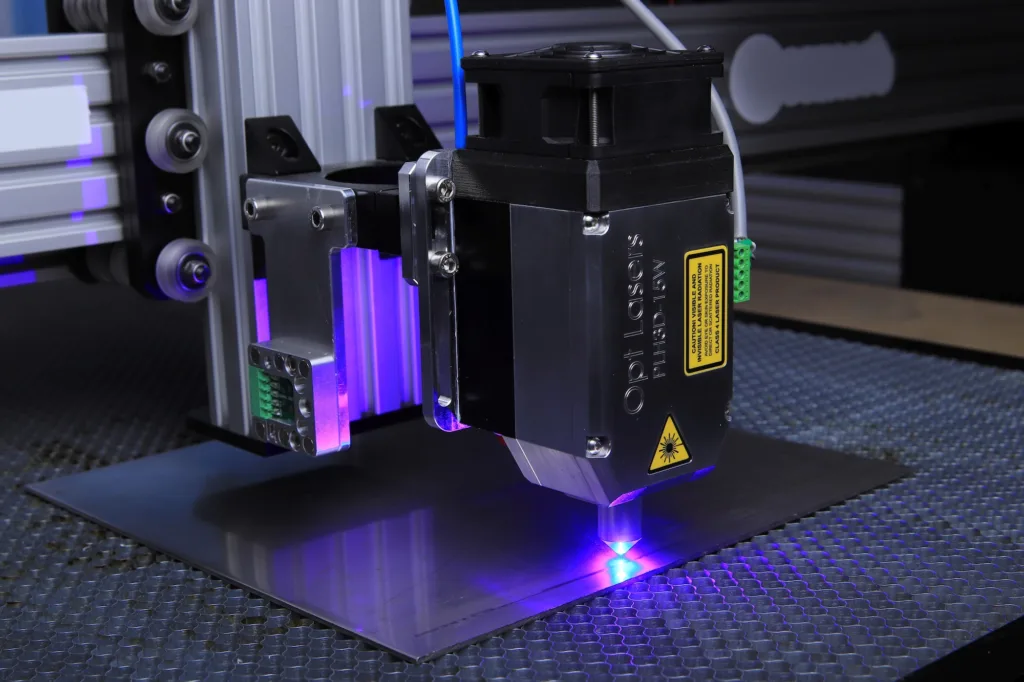

Laser marking is a non-contact, high-precision process that uses a focused laser beam to etch, engrave, or mark a variety of materials permanently. The process involves altering the material’s surface properties without causing any physical damage, making it ideal for delicate items or materials that are sensitive to mechanical stress.

Laser marking offers a level of accuracy and detail that surpasses traditional marking methods, such as stamping, engraving, or chemical etching.

Types of Laser Marking

There are several types of laser marking techniques used in the industry, each catering to specific applications and material types.

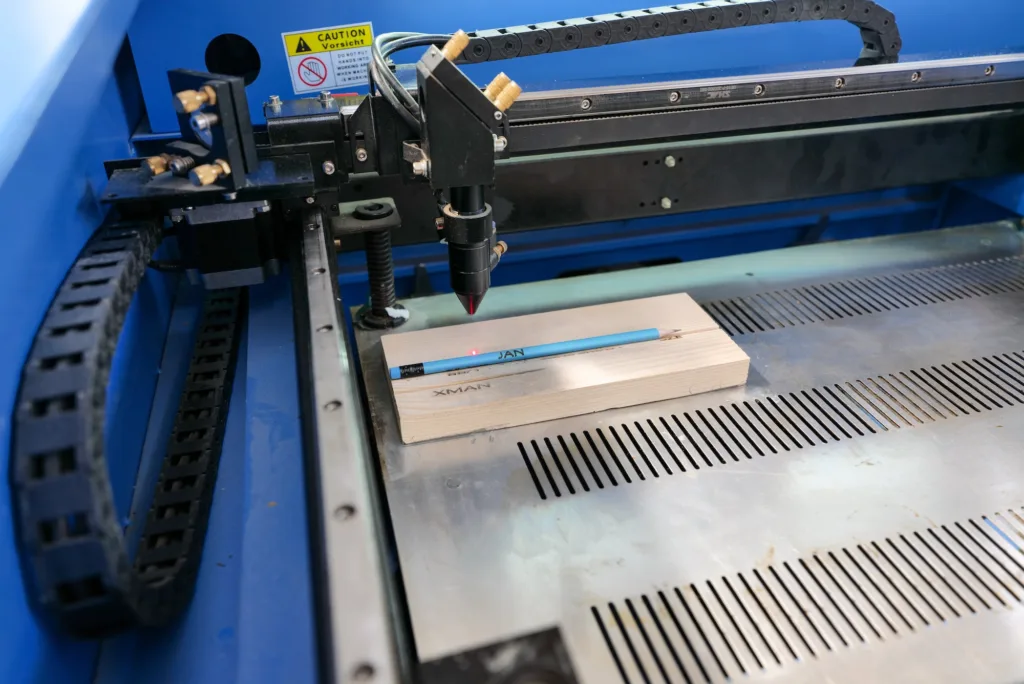

Laser engraving involves removing material from the surface to create a visible mark. It’s commonly used for metals, plastics, wood, glass, and ceramics. On the other hand, laser etching is similar to engraving but often results in a shallower mark. It’s used for materials like anodized aluminum, stainless steel, and some plastics.

Laser Annealing is another technique commonly used with metals, particularly stainless steel and titanium. It changes the color of the material without removing any substance. While laser foaming is typically used for plastics, this method creates a raised, textured mark by expanding the material’s surface.

Applications of Laser Marking

Laser marking services find applications in a wide range of industries due to their versatility and precision. Some of the common uses include:

Product Identification and Branding: Laser marking allows businesses to mark their products with logos, serial numbers, barcodes, QR codes, and other essential information for identification and traceability.

Medical and Aerospace: In industries where precision and safety are paramount, laser marking is used to mark surgical instruments, medical devices, and aerospace components with part numbers, lot codes, and manufacturing information.

Automotive: Laser marking is widely used in the automotive industry to mark critical parts, such as engine components, chassis, and transmission parts, ensuring easy tracking and quality control.

Electronics and Semiconductors: For electronics manufacturers, laser marking is crucial for marking circuit boards, microchips, and various electronic components.

Jewelry: Laser marking has revolutionized the jewelry industry, allowing intricate designs, personalized engravings, and anti-counterfeiting measures.

Packaging and Labelling: Laser marking is employed in the packaging industry to create clear and permanent markings on packaging materials, ensuring product authenticity and batch tracking.

Benefits of Laser Marking Services

The adoption of laser marking services offers several advantages that make it a preferred choice for various industries:

Precision and Accuracy: Laser marking provides unparalleled precision and accuracy, ensuring consistent, high-quality markings on various materials.

Speed and Efficiency: Laser marking is a fast process, enabling high-speed production lines without compromising on accuracy.

Non-contact Process: As a non-contact method, laser marking eliminates the risk of damaging delicate materials, reducing waste and improving efficiency.

Durability and Permanence: Laser-marked identifiers are resistant to wear, fading, and environmental factors, ensuring long-lasting product identification and traceability.

Eco-friendly and Safe: Laser marking is a clean process that does not involve the use of harsh chemicals, making it environmentally friendly and safe for operators.

Flexibility: Laser marking can handle a wide range of materials, shapes, and sizes, providing businesses with the flexibility to mark diverse products.

Choosing a Laser Marking Service Provider

Selecting the right laser marking service provider is essential to ensure optimal results and a seamless integration into your production processes. Consider the following factors when choosing a service provider:

Experience and Expertise: Look for a company with significant experience in providing laser marking services and a track record of successful projects.

Technology and Equipment: Ensure the service provider uses the latest laser marking technology and equipment to achieve the highest quality results.

Material Compatibility: Verify that the provider can work with the materials used in your industry, as different lasers are suitable for different materials.

Customization Options: Check if the service provider can accommodate specific customization requirements for your products.

Turnaround Time: Inquire about the turnaround time for completing projects, especially if you have time-sensitive production schedules.

Conclusion

Laser marking services have emerged as a game-changer for industries seeking precision, permanence, and efficiency in their product identification and branding processes. From aerospace to jewelry, automotive to electronics, the applications of laser marking are vast and varied.

With its numerous benefits and unmatched capabilities, laser marking technology continues to drive innovation and productivity across industries, ensuring product traceability and customer satisfaction in an increasingly competitive market.

As technology continues to evolve, we can expect laser marking services to further advance, meeting the ever-changing demands of modern manufacturing and product identification needs.